RESEARCH AND TECHNOLOGICAL DEVELOPMENT

PKN ORLEN continued the Petrochemicals Development Programme, its largest ever CAPEX programme, including Olefins III, Phenol II and Aromatic Derivatives as the key projects. The process to select a contractor for Olefins III was at an advanced stage. Contracts were signed with consortia of engineering and technology companies to obtain paid proposals for the lump-sum turn-key engineering, procurement, construction and commissioning (EPC LSTK) of the Olefins III complex. A front-end engineering design was prepared and the EPC contractor selection process was launched for the project to expand phenol production capacity. Currently, the Płock production plant’s annual phenol production capacity is ca. 46,000 tonnes, which is set to increase to ca. 200,000 tonnes after the new project is placed in service. Once completed, Phenol II will increase the output of high-margin products and contribute to expanding PKN ORLEN’s share in the phenol market and strengthening its competitive position in global petrochemical markets. Seeking to extend its value chain and maximise investment returns, PKN ORLEN purchased a licence and front-end engineering design for an isopropanol unit. It will utilise acetone obtained as a by-product in phenol production and convert it into isopropanol, which is a high-margin solvent. Isopropanol will be added to the portfolio of speciality products to meet growing customer requirements. 2020 saw the launch of the strategic Infrastructure Programme, which aims to deploy the necessary infrastructure at the Płock production plant for the Petrochemicals Development Programme and other growth projects. Once expanded, the Płock petrochemical complex will be one of the largest and most advanced in Europe, placing PKN ORLEN at the forefront of petrochemical production in Central Europe.

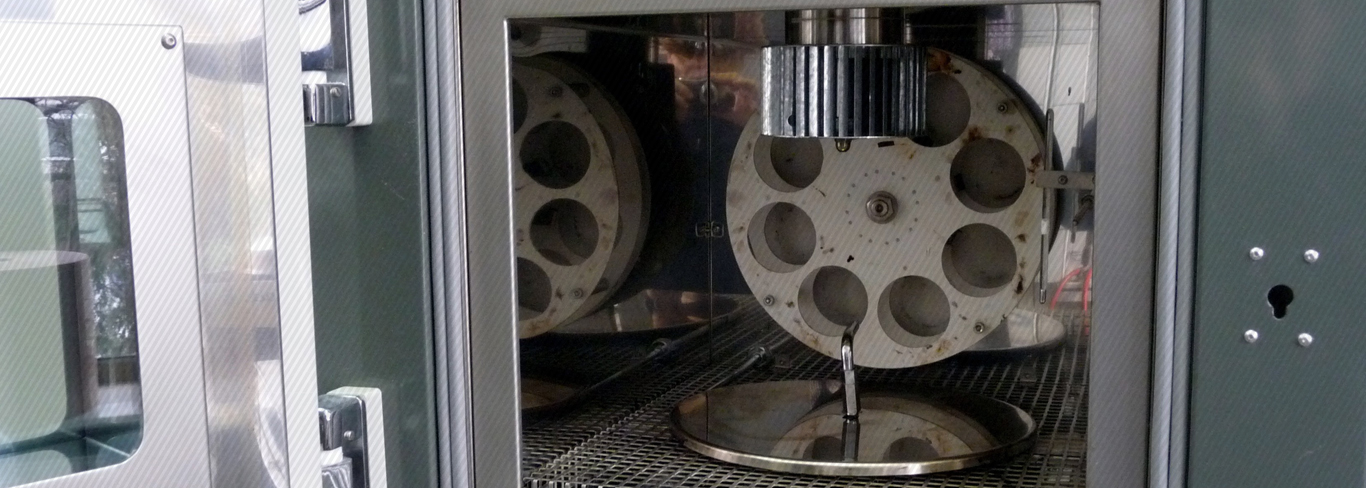

The construction of the Research and Development Centre in Płock was completed, with commissioning commenced in December 2020 and commercial operation started in February 2021. The Research and Development Centre is a key project of the Petrochemicals Development Programme, which will enable PKN ORLEN to further enhance processes, and to develop and implement proprietary technologies and solutions which will deliver measurable financial benefits in the future, and will also serve as a modern platform for cooperation between PKN ORLEN and the world of science and business.

In 2020, PKN ORLEN strengthened its position on the international fuel market by maximising refinery performance, expanding refining assets and modernising existing units. Construction of the key visbreaking unit was launched to achieve higher crude conversion rates and increase yields of light products. In the visbreaker, vacuum residue, which has so far been used to make heavy fuel oils and bitumen, will be processed into high-margin products: gasoline and diesel oil. Work was carried out to upgrade the hydrocracking unit and diesel hydrotreater (HON) in order to increase margins and ramp up diesel oil production. A front-end engineering design for the upgrade of the vacuum residue hydrodesulphurisation (HOG) unit was purchased with a view to enhancing the unit’s process efficiency. In 2020, a front-end engineering design was prepared and contracts were signed for the MaxEne project. The use of the innovative MaxEne technology will contribute to achieving higher margins on fuels and petrochemicals at the Płock production plant.

An important element of PKN ORLEN’s growth was the increase in biofuel production, including second-generation biofuels. A process technology for the co-hydrogenation of diesel oil fractions with vegetable oils was developed. Work was carried out to build the Company’s own unit for the production of biocomponents with use of the Hydrotreated Vegetable Oil (HVO) technology. Under the project, the process of selecting the contractor commenced.

In 2020, research and development work was carried out in cooperation with Polish and foreign universities, research institutions and in close cooperation with ORLEN Group companies. In line with the adopted Strategy, research was carried out on new technologies, products and biofuels. PKN ORLEN’s research portfolio also included topics related to the requirements of the generally defined climate policy, as well as the PKN ORLEN’s Decarbonation Policy. The ongoing research focused on technologies for capturing carbon dioxide emissions and their use as feedstock for manufacturing valuable chemicals. The research also covered technologies for the production of green, emission-free hydrogen and intensifying the re-use of secondary products in the light of the priorities of the circular economy. Efforts were also taken to proactively explore innovative technological solutions. A number of projects, meetings involving Polish universities, research institutes, research support foundations, technology transfer centres and technology companies were organised.

In 2020, digitisation of the Płock production plant continued with a view to optimising production processes. Under the Przemysł 4.0 (Industry 4.0) Programme, projects were carried out to implement advanced data analysis tools for modelling and predicting optimum process parameters to achieve cost and product optimisation. Among other things, work was carried out to implement a system to manage key process parameters on the units which are key money makers in terms of production margin.

Energa Group

The Energa Group continued the Bystra NEDO Battery Energy Storage project, designed to acquire expertise on the feasibility of using energy storage technologies in order to improve the operational flexibility of the Polish Power System. The project is expected to lead to the construction of an energy storage facility on the site of the Bystra wind farm.

On March 10th 2020, Centrum Badawczo-Rozwojoweim. M. Faradaya Sp. z o.o. (a research and development centre) signed an agreement with the National Centre for Research and Development (NCBiR) whereby EU funds are to be provided to co-finance construction of a modular unit of hydrogen-generating reversible solid oxide cells, which is the first hydrogen project at the Energa Group, co-financed with EU support. The purpose of the project is to develop and build a power-to-gas (P2G) system for generating hydrogen using process steam, based on the solid oxide cell (SOC) stack with cells operating as electrolysers, designed also for the operation as a reversible solid oxide cell (rSOC).

In 2020, Energa OZE S.A. continued its innovative project to install solar photovoltaic panels with a capacity of up to approximately 1 MW on a water reservoir. The purpose of the project is to develop and test technologies for floating PV units in order to effectively use water reservoirs (including post-mining reservoirs) in the future. The project is an innovation and a pioneering venture of this type in Poland. The pilot unit, developed by Energa OZE S.A. in 2018, is located at the Łapino Wind Farm and has a total capacity of 3.92 kW. Four small PV units were assembled, each consisting of four photovoltaic panels (a total of 16 panels of 245 W capacity each). The project is being carried out in cooperation with the Centrum BadawczoRozwojoweim. M. Faradaya R&D centre. The parties work together to develop innovative floating buoys on which solar photovoltaic panels will be mounted.

In 2020, Energa Operator S.A. continued its demonstration project EUniversal, whose objective is to develop network flexibility and potential to use flexibility services in the energy market. The project is being implemented as part of an EU consortium consisting of 18 energy sector entities, and its research and innovation activities are co-financed from the EU Horizon 2020 programme. It is designed to enable changes to be made in the consumption or generation of energy, including that generated from renewable sources, in order to eliminate risks to the operation of power infrastructure.

In December 2020, Energa Invest Sp. z o.o. announced that it would receive nearly PLN 3 million from the National Centre for Research and Development (NCBiR) as partial funding for the implementation of new solutions in the construction of high-voltage columns: innovative special purpose structures, single and double-track columns for high voltage lines, together with a communication system powered directly from the high voltage line.The purpose of the project is to develop innovative special-purpose structures for single- and double-track columns for high voltage lines, together with a communication system powered directly from the high voltage line, based on results of industrial research and development work involving the concept, simulation, verification and prototype of the new structures and power supply systems, ready to be placed on the market, which will enhance the competitive position of Energa Invest Sp. z o.o.. The Gdańsk University of Technology will be the partner of Energa Invest Sp. z o.o. in the project.

On December 8th 2020, Energa S.A. entered into a confidentiality agreement with the National Centre for Research and Development (NCBiR). The parties intend to start work on joint arrangement and co-financing of various credit facilities under research and development programmes. The goal is to increase the scale of industrial implementations of innovative solutions by entering into an agreement auxiliary to the agreement on the parties’ cooperation that will involve provision of information whose transfer, disclosure or use may be detrimental to the parties’ interests. Energa and NCBiR decided to execute the confidentiality agreement to set out the conditions for mutual disclosure of confidential information.

ORLEN Unipetrol Group

The ORLEN Unipetrol Group completed the construction ofthe Polyethylene 3 (PE3) unit. which is to ultimately produce 270,000 tonnes of polyethylene per year; it has replaced the oldest part of the line, with a capacity of 120,000 tonnes. With the new unit, the capacity of the Litvinov plant will rise to 470,000 tonnes of polyethylene per year. In SpolanaNeratovice, the construction of a new gas-fired heating plant was completed; it will replace the existing lignite-fired unit, which will reduce air emissions.

In 2020, the ORLEN Unipetrol Group carried out research and development work. Key research areas were production of biofuels and green hydrogen, processing of alternative feedstocks for production of fuels, monomers and polymers, in accordance with the circular economy regulations.

The ORLEN Unipetrol Group’s Centre for Research and Education (ORLEN UniCRE) sought to find optimal bio-component technologies, including for processing pure vegetable oils and used cooking oils for the production of hydrogenated vegetable oil (HVO), as an optimum alternative to fossil diesel oil. Research was also carried out on the use of biomass and municipal waste.

In 2020, the Unipetrol Group carried out an operational test of HVO processing in the steam cracker unit, which yielded the first ‘green’ monomers. It also completed the pilot installation of a plastic waste pyrolysis unit. The solution will enable further research in this respect, detailed analysis of the materials produced, and thus identification of their appropriate application in other processes. Another important strategic task was the development of green hydrogen production. The Unipetrol Group perceives organic hydrogen as an appropriate alternative for future carbon-free economy and mobility. In 2020, the Unipetrol Group signed a contract for the construction of the first three hydrogen stations at BENZINA ORLEN Group service stations, to be launched in 2021. ORLEN UniCRE commenced a feasibility study for the construction of a 52 MW solar photovoltaic power plant with a 20 MW electrolysis unit for the production of green hydrogen.

In 2020, the Unipetrol Group commenced construction of a new DCPD (dicyclopentadiene) unit with a capacity of 22,400 tonnes per year. DCPD is used in the production of hydrocarbon resins (colour asphalt, reinforcing paints), unsaturated polyester resins (boat components, sanitary products), EPDM (ethylene propylene diene monomer) elastomers (car buffers, roof coverings) and COC (cyclic olefin copolymers) (transparent materials). These are the sectors where the Unipetrol Group will focus its research and development. On a pilot distillation unit placed in service in 2020, the Unipetrol Group prepared commercial samples for future customers. The unit has enabled effective technology validation and will support further testing and product research and development.

The Polymer Institute Brno (PIB) research centre focused on supporting the activities of the Polyethylene 3 (PE3) unit and product development. Other projects included the production of PLA (polylactide) at the ORLEN Group as an ingredient to improve the biodegradability of the polymer, which is also produced from renewable material. PIB also focused on mechanical recycling of plastics. This type of recycling is a serious challenge which, if met, will contribute to the circular economy objectives.

The Unipetrol Group also engaged intensively in establishing closer cooperation with universities and research institutions, including foreign ones. In 2020, it signed an agreement enabling the Faculty of Mechanical Engineering of the Czech University of Technology to participate in the University Center UCT Prague – Unipetrol programme.

ORLEN Lietuva

In 2020, ORLEN Lietuva continued its project to construct a new hydrocracker. A tender procedure was carried out to select the contractor based on the front-end engineering design received. Implementation of this technology will increase the rates of crude oil conversion, reducing the output of heavy refining fractions and maximising margins. The project will also help meet the new, more stringent quality requirements applicable to the production of heavy oil fractions imposed by the IMO regulations.

The construction of an alkylation unit producing high-octane component for the production of motor gasoline was launched. Work was continued to prepare for final investment decision on the ‘Bottom of the Barrel’ unit, intended to maximise the refinery’s margins by increasing crude conversion rates.

In 2020, the first co-processing test was run on the LK2 diesel hydrotreater. As a result, a blend of diesel oil and HVO (biofuel) was obtained. The test was successfully completed, and the BV certificate was received and confirmed. After the beginning of the winter season, arctic diesel oil blended with HVO was placed on the market. The new diesel oil is of higher quality compared with the one blended with RRME.

PPF Splitter technology was adjusted to obtain better quality propylene. The technology of the PrimeG (cracked gasoline desulfurisation) process was changed, which reduced the unit’s energy intensity. A few projects were also carried out to improve the refinery’s efficiency (replacement of heat exchangers) and reduce CO2 emissions.

ANWIL

ANWIL made further progress on development work to increase its annual output of fertilizers from 0.5m tonnes to approximately 1.5m tonnes. In 2020, the project saw continued construction work on three key units of the complex, i.e. the nitric acid, neutralisation, and granulation units, and reached a completion status of more than 44%. Expansion of the fertilizers segment was prompted by growing demand for these products. As regards the existing units, the finished upgrade of the ammonia A line will support maintaining high volumes of ammonia production. Upgrade of the B-1304A steam superheaterwas completed, contributing to reduced energy consumption and lower NOx emissions. Tests of production of fertilizers with aluminium and potassium sulfates, intended to improve the mechanical properties of the fertilizers, ended with a positive result.

In 2020, ANWIL S.A. also carried out analytical and pre-project activities to expand its PVC production capacity to 420,000 tonnes per year, as part of the ORLEN Group’s strategic Petrochemicals Development Programme. The ninth electrolysis unit was launched at the chlorine plant, which helped improve the operational availability of the plant and the efficiency of chlorine production.

In cooperation with PKN ORLEN, a project to construct a hydrogen hub at ANWIL S.A. was launched. It is expected to enable the ORLEN Group to enter the Polish carbon-free fuels market and result in the development of a new product: automotive hydrogen fuels. The company filed an application for non-repayable funding under the CEF Transport Blending Facility. At the end of the year, the project was in the procurement phase for selection of the EPC contractor.

ANWIL S.A. also carried out the necessary preparatory work to launch feasibility studies for the 120+ Ammonia project, which will seek the most efficient technologies to increase ammonia production capacity. Work was continued in cooperation with the Warsaw University of Technology and the commercial partner on solutions to improve the productivity and energy efficiency of ammonia synthesis.

As part of the development of innovation tools, cooperation was established with two accelerators which match startups with industrial companies. As a result of this cooperation, the parties signed a contract under which work was carried out on an innovative solution dedicated to precise fertilisation maps using data from stationary metering (weather) stations.

As regards the development of fertilizers, ANWIL S.A. acquired a new partner for agrotechnical research; cooperation was also continued with the Institute of Soil Science and Plant Cultivation in Puławy. A number of tests were carried out with additives which improve fertilizer properties, and research into the control of ammonium nitrate crystallisation was launched with support from the Warsaw University of Technology. As part of its fertilizer production development programme, ANWIL S.A. prepared the Programme and Spatial Concept for the Construction of a Fertilizer Test and Production Unit, which will be an important element of the company’s development programme for the coming years.

In the area of plastics development, research work on the injection of ammonia water into recovery pipelines was finished with a positive result, and design work was launched to enable the CID (Continuous Initiator Dosing) tests to be carried out. Research work was completed on the recovery of evaporative heat from wastewater, the replacement of an antifoaming agent for the polymerisation process, and on a bio-based composite for a PVC matrix. Work was commenced on a project to develop a technology for the production of vinylidene chloride from production waste. Due to its potential, the project was submitted to the ‘Rapid Path’ competition announced by the National Centre for Research and Development. Research was also commenced into a hydrochloric acid concentrating method (in the VICARB unit), PVC dust explosiveness, migration of plasticiser from plasticised PVC applications and PVC-based formulations with resistance to bacteria and fungi.

ORLEN Południe

ORLEN Południe continued construction of a plant for making bio propylene glycol in Trzebinia. The new plant with an annual capacity of 30 thousand tonnes will be of strategic importance to the ORLEN Group. Work on construction of the hydrogen plant was nearing completion.

Activities relating to advanced biofuels included further work on a project to construct a unit for the production of biodiesel from used cooking oil with an annual capacity of 30,000 tonnes. Working documentation was purchased and administrative permits were obtained; a procurement procedure was initiated to select the contractor for the construction on a PC basis. As part of extension of the existing plant for the production of fatty acid methyl esters (the first phase of the unit extension to increase annual capacity by 25,000 tonnes), a contract was signed with the contractor. The relevant procedures were also initiated to purchase a licence and a front-end engineering design for further expansion of the unit (the second phase to increase the capacity by an additional 100,000 tonnes per year through the construction of a new unit). With regard to the objective of extending the value chain in the production of fatty acid methyl esters, a decision was made to build the company’s own rapeseed oil press plant. Land was acquired for the construction of a press plant with an annual capacity of 200,000 tonnes, with an optional extension to 300,000 tonnes. The construction of the 2G bioethanol unit was continued. The front-end engineering design was purchased to build a plant for producing bioethanol from grain straw and procurement processes were launched for the construction of a 2G bioethanol unit with a power supply system, biogas plant and wastewater treatment plant. As regards the development of a new biogas business line, the first biogas plant in Konopnicawas acquired. As part of the greenfield development path, a biogas plant under construction was acquired in Głąbowo and cooperation with KOWR (National Support Centre for Agriculture) was extended to analyse further locations.

Within the framework of the project to develop a treatment technology for glycerine derived from UCOs and animals fats the project’s Phase 1 was completed in cooperation with the Oil and Gas Institute of Kraków, where a treatment technology for glycerine derived from UCOs and animal fats was developed under laboratory conditions. Work continued on biodegradable anti-caking agents for the fertilizers industry, financed under the INNOCHEM Sector Programme. Final anti-caking mixtures were selected for testing by fertilizers manufacturers. Phase 2, i.e. construction of a pilot unit for the production of lactic acid, was launched as part of a project to develop biotechnology-based conversion of organic raw materials into lactic acid using microorganisms, co-financed under the INNOCHEM Programme. Work was also carried out in cooperation with the Polish Academy of Sciences to develop a production technology for polyhydroxybutyrate biopolymer (PHB).

ORLEN OIL

ORLEN OIL continued research work to implement new and modify existing products and to define new directions for the development of lubricant technologies. A number of measures were taken with a view to continuously improving the quality of oils in response to current demand reported by the sales division. Key research expenditure was incurred within the company’s strategic segments, in particular the segment of motor oils for passenger cars, and of universal and speciality industrial oils. In 2020, technologies for 73 new products were developed and implemented, including speciality and universal industrial oils, service fluids, lubricants and other oils. 93 approvals were obtained for ORLEN OIL’s products from manufacturers of machinery, equipment and engines.

Also, collaborative partnerships were maintained with research and scientific institutions, as well as Polish and international standardisation, certification and opinion-making institutions that influence the development directions for lubricants. Co-financing from the National Centre for Research and Development (NCBiR) was obtained for a project to improve the operational characteristics of industrial lubricants with the use of nanoadditives under the Smart Growth Operational Programme 2014–2020. The project is being implemented in a consortium with the Łukasiewicz Research Network – the Blachownia Institute of Heavy Organic Synthesis. It focuses on the development of a line of lubricant products where conventional enhancing additives will be replaced or supplemented with nanocomponents. The line will include three product types commonly used in the manufacturing and automotive industries: plastic lubricants and machining (emulsifying and non-emulsifying) oils.

ORLEN Asfalt

ORLEN Asfalt carried out research work at Paramo to test the Polish HiMA(highly modified asphalt) bitumen formulation with feedstocks from Litvinov. After a positive outcome of the production and quality tests, Paramo started production of PMB HiMA 65/105-80 and 45/80-80. This enabled ORLEN AsfaltČeskáRepublika to start supplying this product to the Czech market and for export, mainly to Switzerland. In 2020, ORLEN Asfalt participated in a six-party research agreement on new applications of highly modified HiMAbitumens in the construction of national roads, concluded between research institutions (Warsaw University of Technology, Gdańsk University of Technology, and Road and Bridge Research Institute) and industrial companies (ORLEN Asfalt, GrupaLotos and BUDIMEX). The project was completed in December 2020 and its implementation was launched, including at the Technology Department of the General Directorate for National Roads and Motorways (GDDKiA). In 2020, work was undertaken to identify new areas of application of ORBITON HiMA polymer-modified bitumens in road construction and to test new technologies using ORBITON HiMA in order to expand the market and increase sales of this product.